3D printers are now affordable and more user-friendly than ever before, but that doesn’t mean there aren’t some pitfalls still out there for people new to the hobby—or those who want to do serious business!

There’s always something more to learn about 3D printing, and I’m learning (sometimes hard) lessons every day, but I think there are a few that should really be pushed to the top of your awareness if you’re planning on buying a 3D printer.

8

Getting Build Volume Wrong

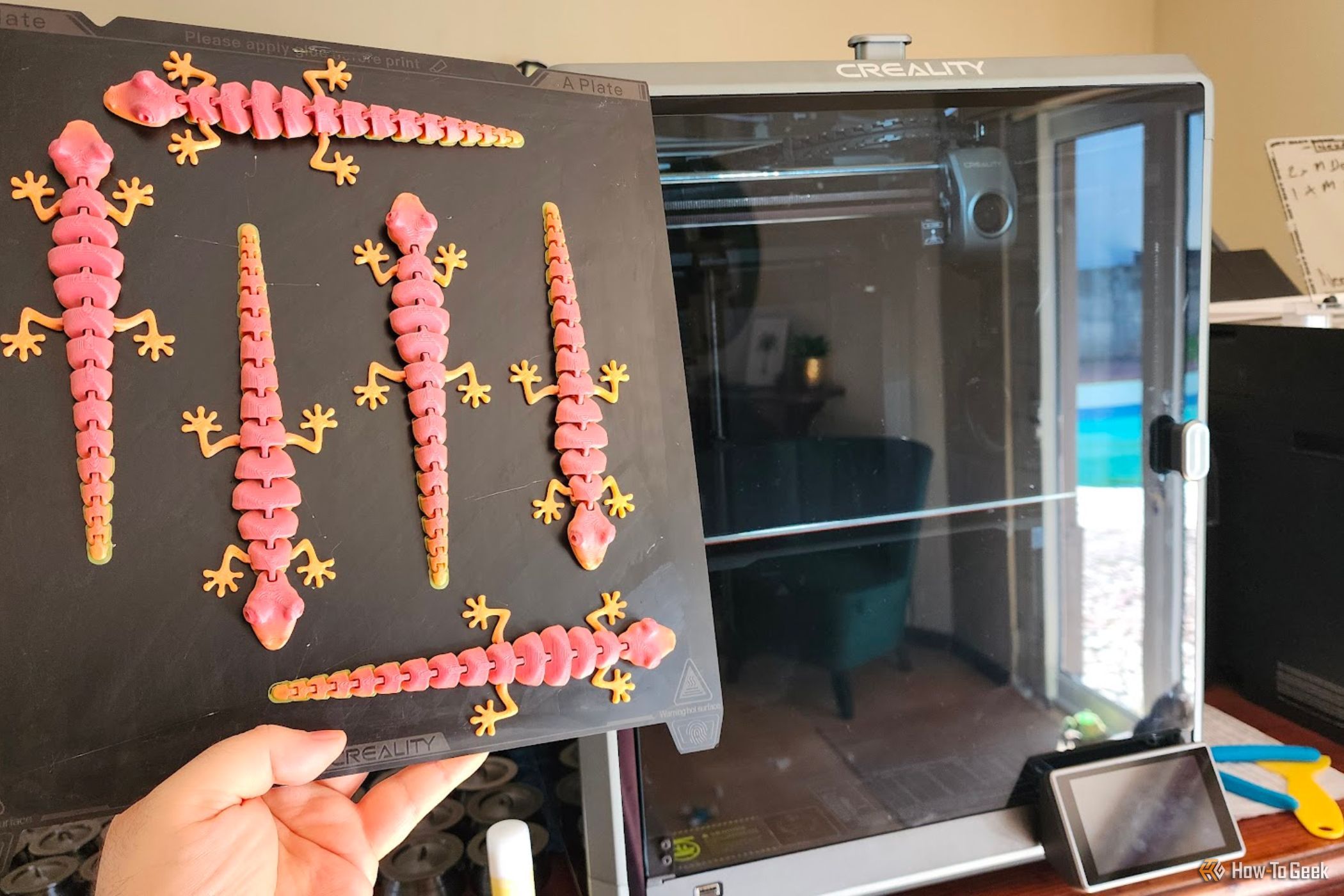

The build volume of your printer is the maximum size within which it can create 3D-printed objects. It’s calculated by multiplying the length, width, and height of the build volume, which gives you the cubic centimeters or inches you have access to for printing. If you buy a printer with a volume that’s too small for your needs, you’ll end up having to print models in pieces, gluing them together later.

It’s not just about the total volume either. Do you need a tall build volume, or does the build-plate size matter the most? Do you want to print single large objects like masks or helmets or do you want to print multiple copies of small objects? If you get it wrong, your options are very limited.

7

Not Checking Material Compatibility

Most people are looking for an FDM (Fused Deposition Modeling) 3D printer, which is a printer that takes a filament and uses it to print objects in layers. That sounds simple enough, but not all filaments are the same!

There are several types of filament, of which PLA and ABS are the most popular. However, there are soft materials like TPU, and even materials that contain metal or carbon fiber.

Any modern 3D printer will have specifications related to the maximum temperature it can heat a filament to, as well as the maximum build plate temperature. It’s also important to know the hardness of your nozzle, since some materials require hard nozzles or they’ll wear it out fast.

If you buy a printer that can’t get hot enough or otherwise isn’t officially compatible with the filaments you want to use, you’ll get unusable results and will either have to modify or replace the printer.

6

Buying the Wrong Type of Printer

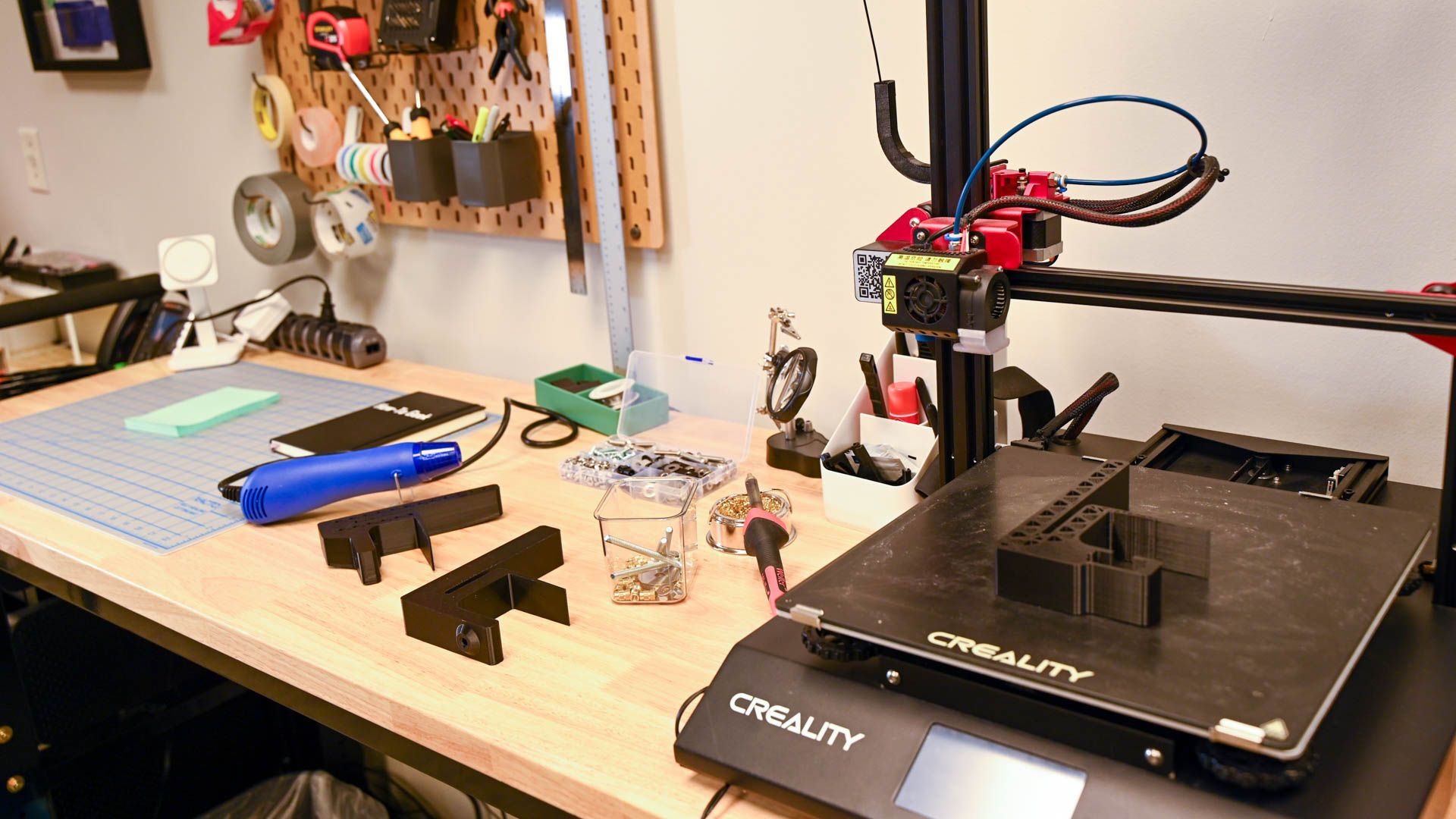

There are a huge number of 3D printer designs, even if we ignore things like resin printers and just look at FDM models. There are the so-called “bed slingers” which move the entire print bed back and forth as part of the printing process. There are Cartesian printers, which are now a rather obsolete design, but are still quite cheap, and then the latest Core XY printers, which are fast and accurate, but will cost you a pretty penny. There are also weird printers like Delta Robots, which aren’t that common but have their specific strengths and uses.

I recommend you read Everything You Need to Know About 3D Printers to prepare yourself with the basic knowledge you need to pick the right type of printer.

Related

Resin vs. Filament 3D Printers: Which Is Better?

Of course, there’s always the easy answer of “why not both?”

5

Picking the Wrong Spot for Your Printer

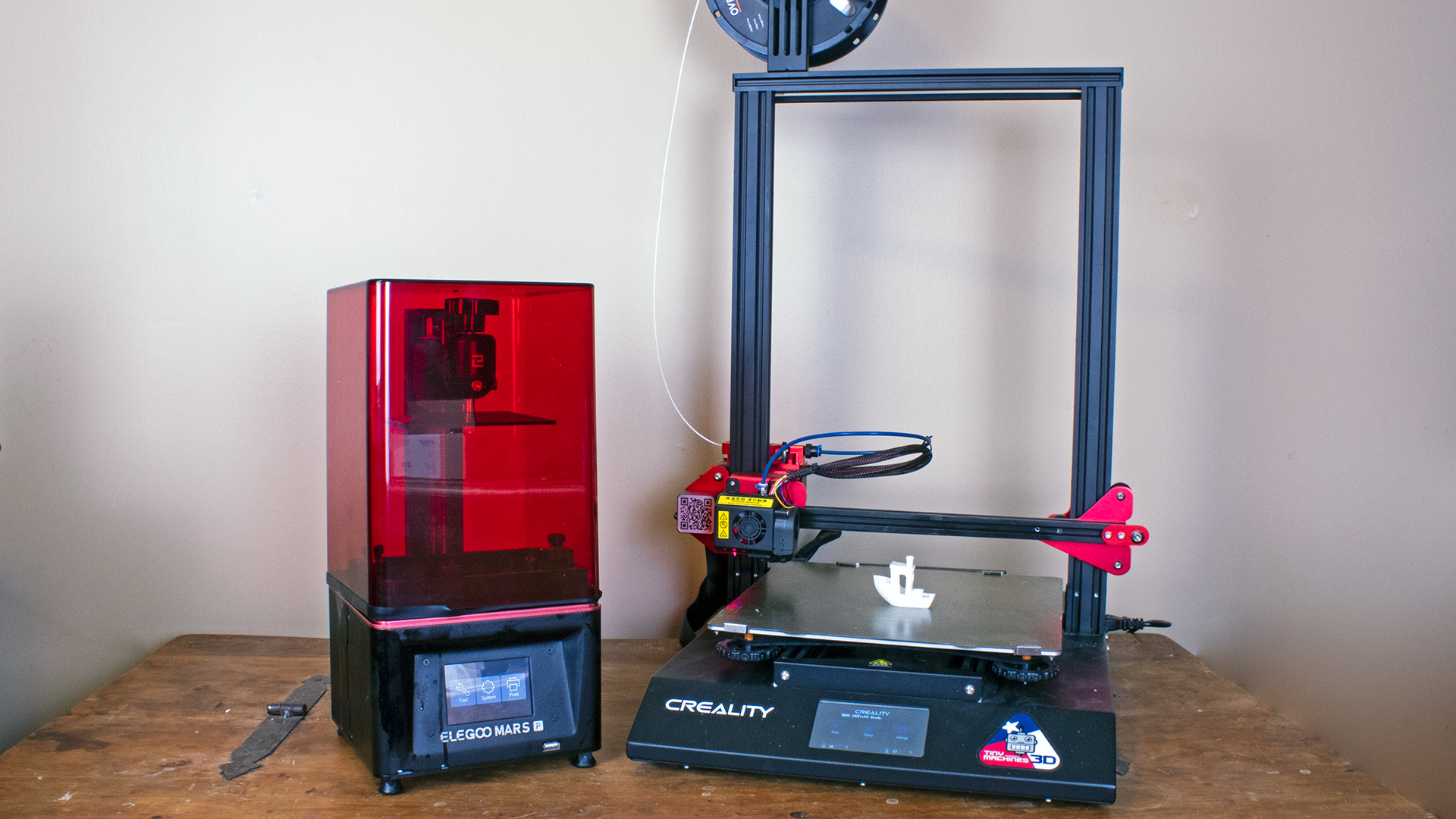

As with many things, with 3D printers it’s all about location, location, location. Here you can see my two current printers that I have set up in a dedicated hobby room.

Printers can be quite noisy, but when I close the door to the room, you can’t hear these two machines working away through the night. Likewise, ventilation is important, so I have it right in front of a window, which I can crack open a little if I want to ensure some of the fumier filaments don’t cause buildup in the room.

You also need a solid table, especially with the new Core XY style printers, as these both are, because they can cause a lot of vibration thanks to the rapid reciprocation of the print head. Make sure you have a suitable spot that’s good for the printer, and also good for your sanity.

4

Not Factoring in Materials and Accessories in Your Budget

The price tag of your new 3D printer isn’t the total cost of ownership and operation. It’s not even the starting cost! You need to take into account what your initial materials will cost, and if you need to buy accessories. Most printers come with some basic tools, but these are rarely good enough for long-term use.

Filament rolls are the obvious cost for FDM printers, but also consider the wattage, so you can calculate how much electricity you use to print something. The exact additional costs will vary from one printer to the next and also depend on your exact needs, but if you’re budget doesn’t have much leeway, you can run into trouble if you only consider the printer’s cost itself.

3

Forgetting to Check Parts Availability and Support

Chances are that your 3D printer was imported from another country—probably China. This means that you aren’t guaranteed local parts and service availability. This is crucial because you will have to service the printer regularly, and you will absolutely need parts on a semi-regular basis depending on what goes wrong, or how much wear and tear the machine experiences.

Related

What Types of Plastics Work Best in 3D Printing?

At a Maker space in my community, the person who maintains the 3D printer lab has a strong distaste for some types of plastic filament. What is your preference? Does environmental impact come into consideration, at least in regards to waste generated in color changes and failed projects? Are there application specific considerations?

A 3D printer that looks like a great deal can become an expensive paperweight, because no one is offering support for that brand and model where you are. This is why I usually phone my local 3D print shop (they do call-outs) to hear if they support a given model before I even bother considering it.

2

Buying a Printer That’s Too Expensive

With 3D printers, the sky’s the limit when it comes to price. They just get bigger, fancier, and more capable as the price goes up. This makes it very easy to buy a printer that offers more capability than you will ever need.

It is, however, quite a tough line to walk, because you also have to take your potential future needs into account when you decide on a budget and the best printer for that money. However, be wary of gimmicky features such as “AI” features that are perpetually in beta and never work right.

It’s also worth considering that many FDM printers can be upgraded at some point with better components, better software, multi-material capabilities, and more. So it’s worth checking if such future upgrades are possible, so that you can spend less now, and have the option to upgrade later without buying a whole new printer.

Related

Creality K1 Max Review: 3D Printing Goes Mainstream

The Creality K1 Max brings a large build volume and advanced automation to a consumer-friendly budget.

1

Buying a Printer That’s Too Cheap!

Unsurprisingly, there are just as many pitfalls when it comes to buying printers that are too cheap. There are many dirt-cheap FDM printers on the market now, which are fine if you just want to dip your toes into the hobby, but you’re quite likely to be unhappy with both the speed and quality of the prints.

Related

Elegoo Centauri Carbon Review: There’s No Reason to Buy Anything Else

Elegoo blows the bottom out of the market.

It’s only recently that modern Core XY printers have started coming down to reasonable prices, and since you can get a modern 3D printer with all the bells and whistles for between $300 and $600, it makes very little sense to buy an outdated model for, say, $200.

This list is far from comprehensive, but I think it’s a good overall start and I hope it saves at least one person out there some money or time.

:max_bytes(150000):strip_icc()/how-to-fix-it-when-mobile-data-is-not-working-on-a-samsung-8bad7aa98c6b4a7d9457125309b9540c.jpg?w=1174&resize=1174,862&ssl=1)

:max_bytes(150000):strip_icc()/GettyImages-532031035-7887eba55093486880c9d08fa7e55658.jpg?w=1174&resize=1174,862&ssl=1)

Leave a Comment

Your email address will not be published. Required fields are marked *